Order Hotline: 15141139898

Email:2651385331@qq.com

♦Customization : All specifications are customized according to the actual situation of the customer or after investigation, and non-standard customization is supported.

♦Inventory: In stock, nationwide delivery guarantee!

♦Tips:Professional large-scale bearing manufacturer!

Classification

PRODUCT CATEGORY

Contact

CONTACT INFO

contacts:Manager Li

Address: Luogou Village, Taiyang Street Office, Wafangdian City, Liaoning Province

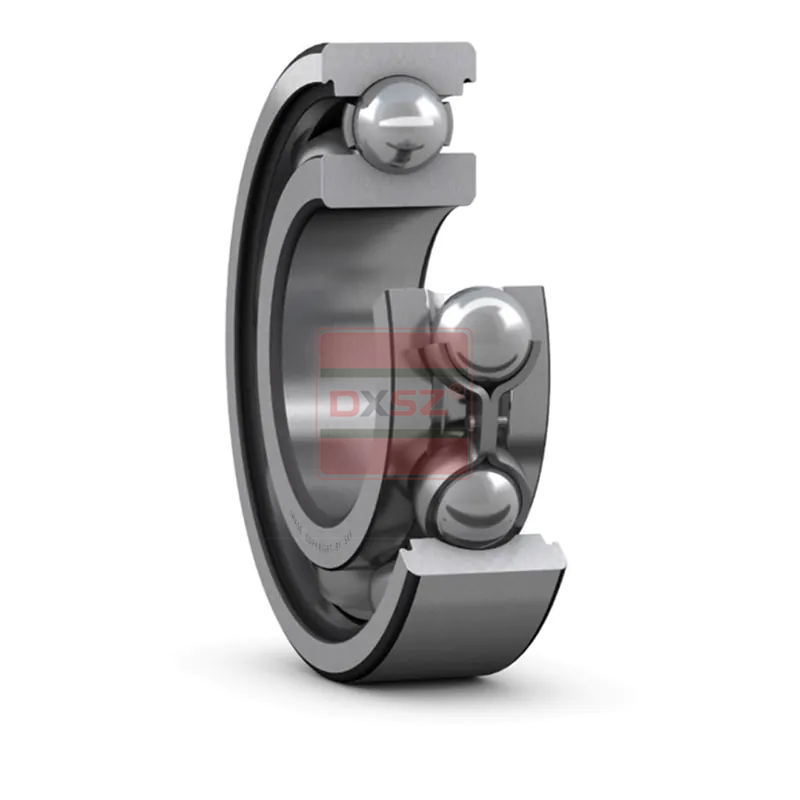

Stainless steel deep groove ball bearings can resist corrosion caused by moisture and other media. Provide closed (with sealed or dust cover) or open design. Open type bearing rings generally have grooves on the side, and can also be equipped with seals or dust covers.

The load-bearing capacity of this type of bearing is lower than that of high chromium steel bearings of the same size.

Stainless steel single row deep groove ball bearings with outer rings and sealing or dust covers on both sides have higher chemical and corrosion resistance. Due to the widespread use, strong versatility, and low friction of deep groove ball bearings, optimization can reduce noise and vibration, thereby increasing rotational speed. It can withstand radial loads and bidirectional axial loads, is easy to install, and requires much less maintenance than other types of bearings. The outer ring with a blocking edge can position the bearing axially in the bearing seat. Embedded sealing can significantly extend the service life of bearings as it prevents grease leakage and contamination from entering.

characteristic:

Improved chemical and corrosion resistance performance

The outer ring with a blocking edge helps the bearing to be axially positioned inside the bearing seat

Embedded sealing can extend the service life of bearings

Typical advantages of single row deep groove ball bearings

Chinese

Chinese Vietnamese

Vietnamese